Optimizing Vial Fill and Finish Capacity with OcyonBio: A Guide to Efficient and High-Quality Pharmaceutical Production

The vial fill and finish process is a critical stage in the pharmaceutical manufacturing landscape. Not only does it require precision and accuracy, but it also determines the final product’s quality, safety, and stability. Optimizing this step with rising demands in the pharmaceutical market becomes paramount. Enter OcyonBio, a game-changer in the industry. By leveraging the information available on OcyonBio.com and insights from their LinkedIn profiles, we have created a comprehensive guide on how OcyonBio can help pharmaceutical companies refine their vial fill and finish capacities.

1. Advanced Automation Solutions

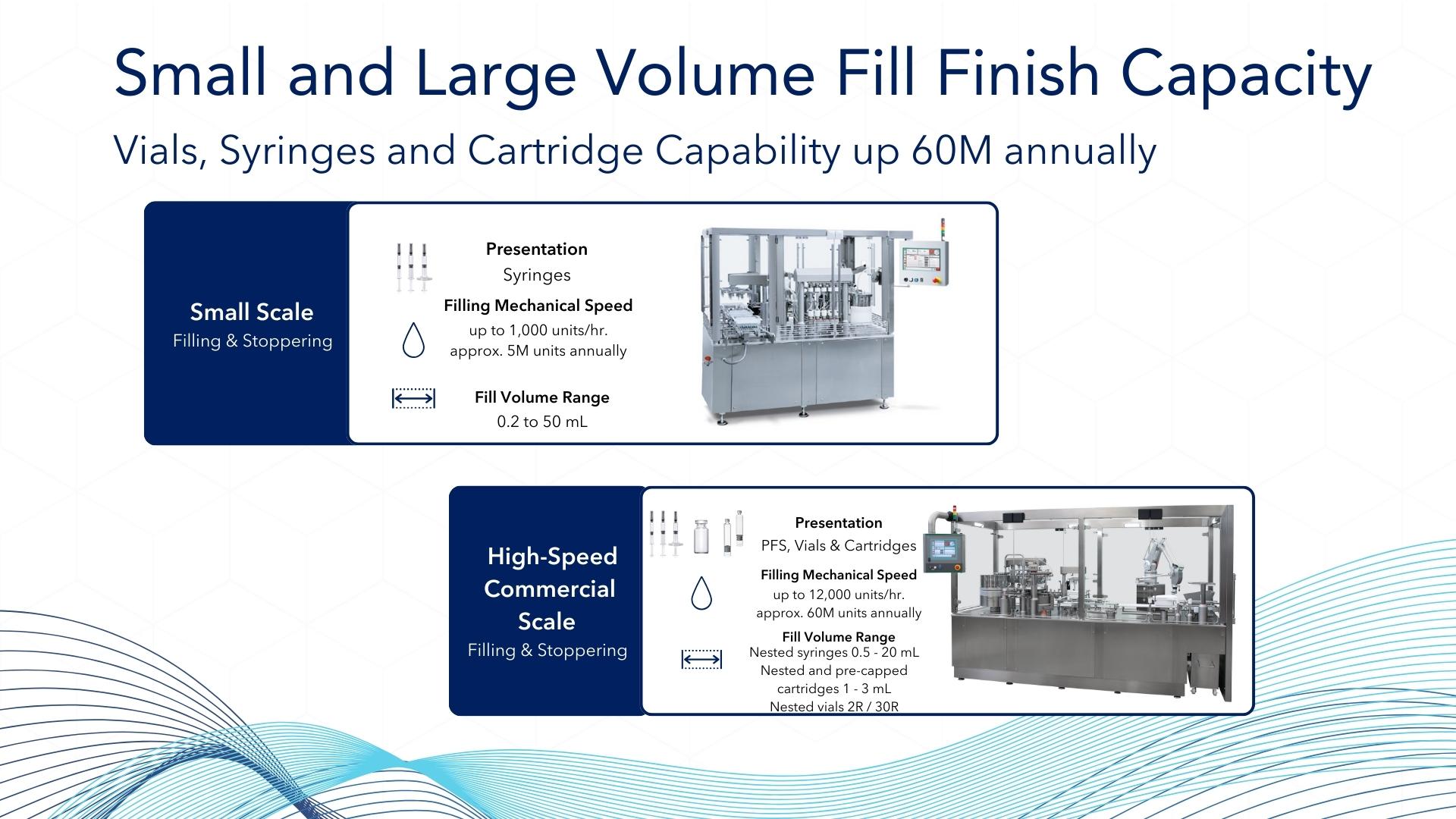

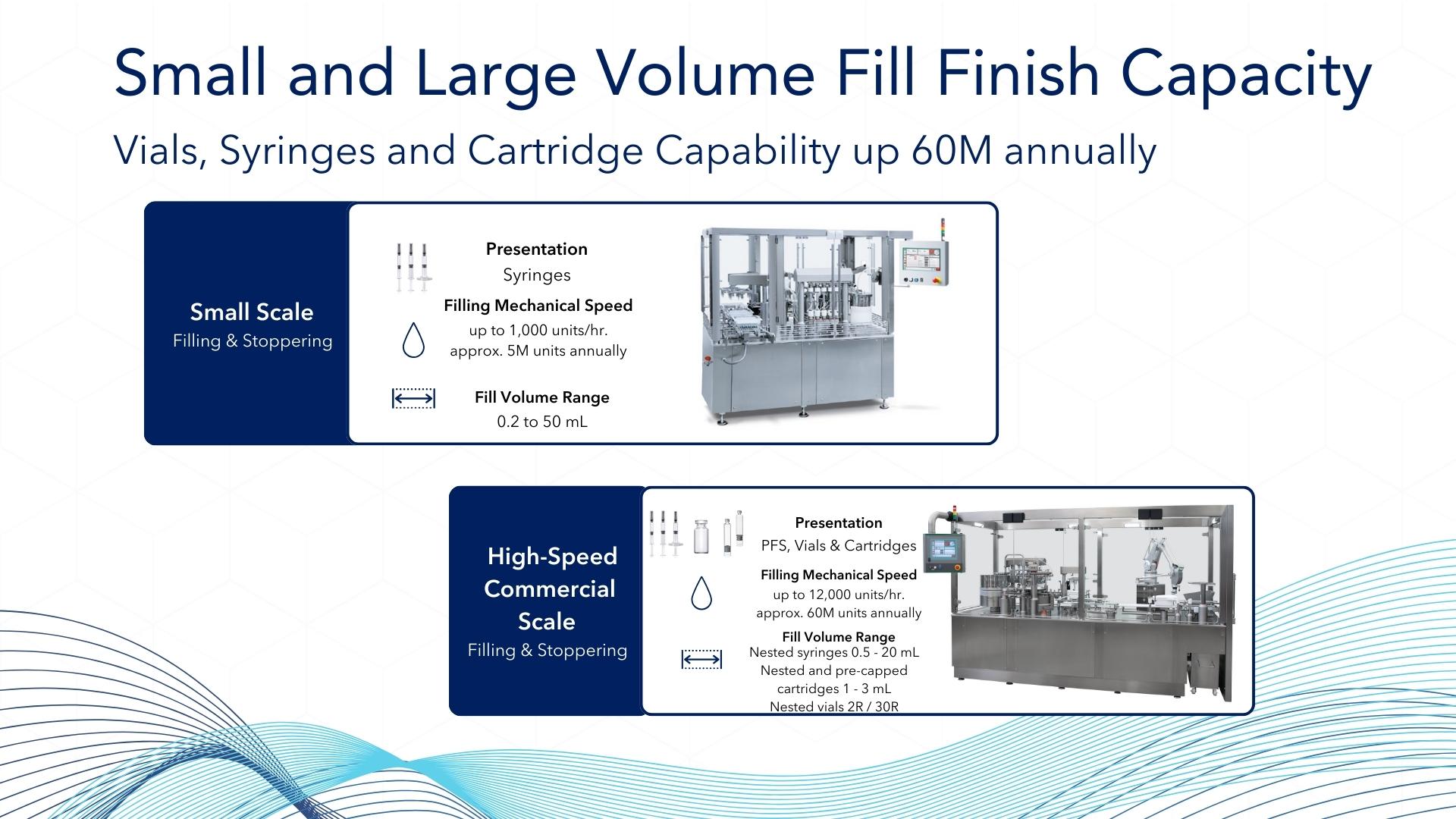

OcyonBio will offer cutting-edge automation solutions for the vial fill and finish process. By integrating these automated systems, pharmaceutical companies can:

- Reduce human errors, ensuring consistency and quality.

- Increase production speed, meeting market demands promptly.

- Achieve cost savings due to reduced wastage and more efficient processes.

2. Comprehensive Training and Support

These training programs equip the workforce with the necessary skills to handle the advanced machinery, ensuring a smooth transition and optimal utilization of the new systems.

3. Data-Driven Decision Making

OcyonBio emphasizes the importance of data in pharmaceutical production. Their systems come with integrated analytics capabilities that provide real-time data on the fill-and-finish process. By analyzing this data, companies can:

- Identify bottlenecks and areas of inefficiency.

- Make informed decisions on process improvements.

- Predict and prevent potential issues before they escalate.

4. Customized Solutions

Pharmaceutical companies are all different, and OcyonBio understands this. As highlighted on their website and LinkedIn, we offer tailored solutions to meet each client’s unique needs, ensuring that the vial fill and finish process is optimized for each specific scenario.

5. Adherence to Global Standards

Quality and compliance cannot be compromised in the pharmaceutical industry. OcyonBio’s solutions are designed keeping in mind global regulatory standards. This ensures that not only is the production process efficient, but it also adheres to international safety and quality norms.

Optimizing the vial fill and finish capacity in a fast-paced pharmaceutical market is not just a necessity but a competitive advantage. OcyonBio, with its advanced solutions, extensive support, and emphasis on data-driven decisions, is poised to be a valuable partner for companies aiming for top-notch production quality. By collaborating with OcyonBio, pharmaceutical manufacturers can ensure that their products are produced efficiently and meet the highest standards of quality and safety.