Navigating the Complexities of Sterile Filling in Pharmaceuticals: The Strategic Role of PDMOs

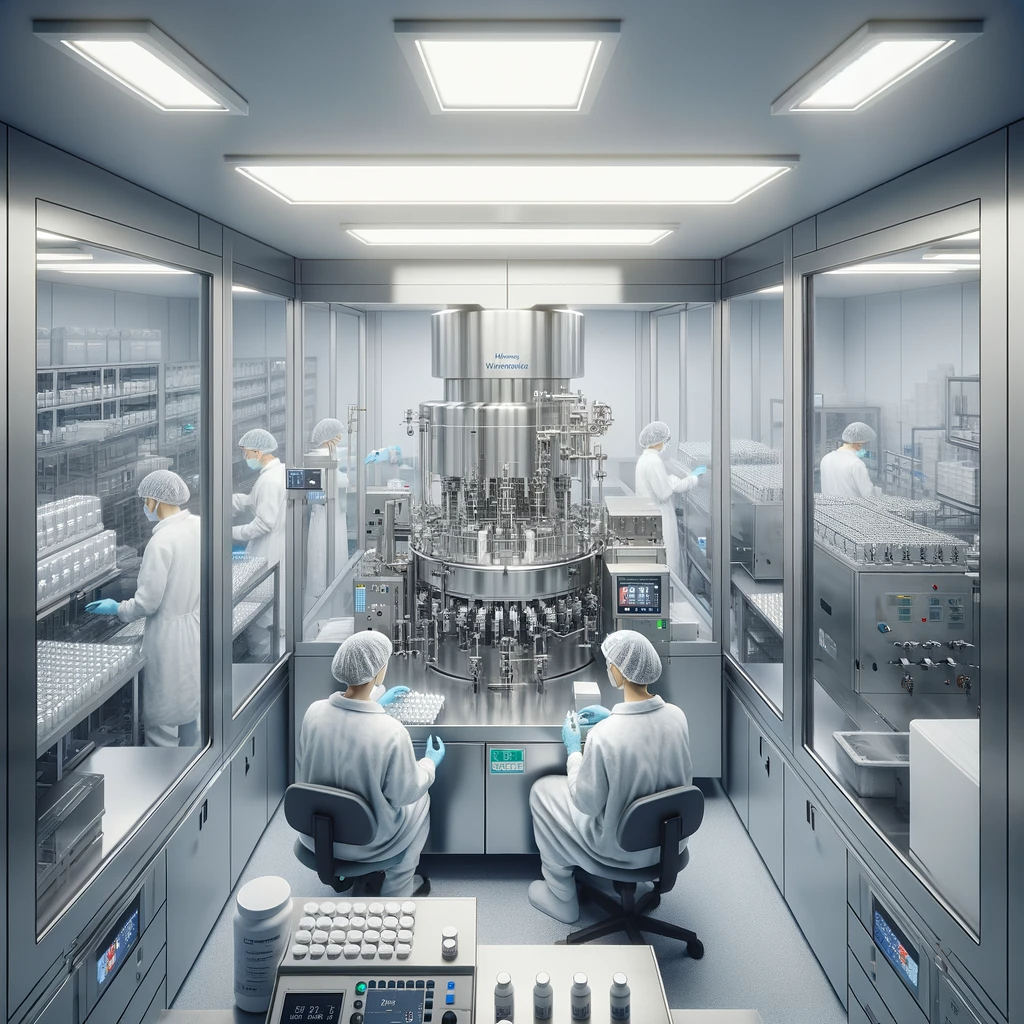

In the pharmaceutical industry, sterile filling is a cornerstone of drug manufacturing, ensuring that products are safe and effective for consumer use. This critical step involves the aseptic filling of drugs into their final containers, which must be meticulously managed to prevent contamination and maintain product integrity. However, the difficulty of maintaining aseptic conditions presents a challenge for many pharmaceutical companies. It requires a blend of advanced technology, specialized expertise, and adherence to stringent regulatory standards. This is where Partnership Development Manufacturing Organizations (PDMOs) like OcyonBio come into play, offering a viable solution to these challenges by providing specialized services that ensure the highest standards of sterile filling.

Difficulties in Maintaining aseptic conditions

Maintaining aseptic conditions in pharmaceutical manufacturing is no small feat. It demands a rigorous adherence to regulatory requirements that are both strict and ever-evolving. Companies must invest into state-of-the-art equipment, maintain sterile environments, and employ highly skilled personnel to oversee the process. These requirements can be daunting, especially for smaller companies that may not have the resources or infrastructure to keep pace with the technological and regulatory demands. The high cost of equipment, the challenge of training and retaining specialized staff, and the constant pressure to comply with new regulations can significantly strain a company’s resources and focus.

Benefits of a Partnership Development Manufacturing Organization

This is where the expertise of PDMO companies like OcyonBio becomes invaluable. OcyonBio can bring a wealth of experience and access to cutting-edge technology and can ensure that pharmaceutical products are filled and packaged in strict compliance with regulatory standards. By partnering with OcyonBio, pharmaceutical companies can leverage this expertise without investing heavily in their facilities or personnel as OcyonBio can offer scalable solutions that can be tailored to the specific needs of their clients, ranging from small-batch productions for clinical trials to large-scale commercial manufacturing, providing flexibility and efficiency that is hard to achieve in-house.

The benefits of outsourcing sterile filling operations to a PDMO extend beyond just access to advanced technology and expertise. It represents a strategic decision that allows pharmaceutical companies to focus on their core competencies, such as research and development and marketing, while mitigating the risks associated with aseptic production. Cost efficiency is another significant advantage, as partnering with a PDMO can reduce the need for capital investments in facilities and equipment, lower operational costs, and provide a variable cost model that aligns with production needs. Furthermore, PDMOs often have established quality management systems and are adept at navigating regulatory landscapes, reducing the regulatory burden on pharmaceutical companies, and accelerating time-to-market for new products.

Conclusion

The complexities of maintaining sterile conditions for fill-n-finish cannot be understated. However, companies can effectively navigate these challenges by partnering with a PDMO. PDMOs offer specialized expertise, advanced technology, and flexible production capabilities that can significantly enhance the ability to deliver safe and effective products. As the industry continues to evolve, the collaboration between pharmaceutical companies and PDMOs like OcyonBio will undoubtedly play a pivotal role in advancing healthcare and improving patient outcomes. Pharmaceutical companies should consider the strategic benefits of such partnerships as they look to optimize their production capabilities and maintain a competitive edge in the market.