Analytical Similarity Gaps and Lessons Learned

Demonstration of Analytical Similarity for Global Biosimilar Applications – Part 2 of 3

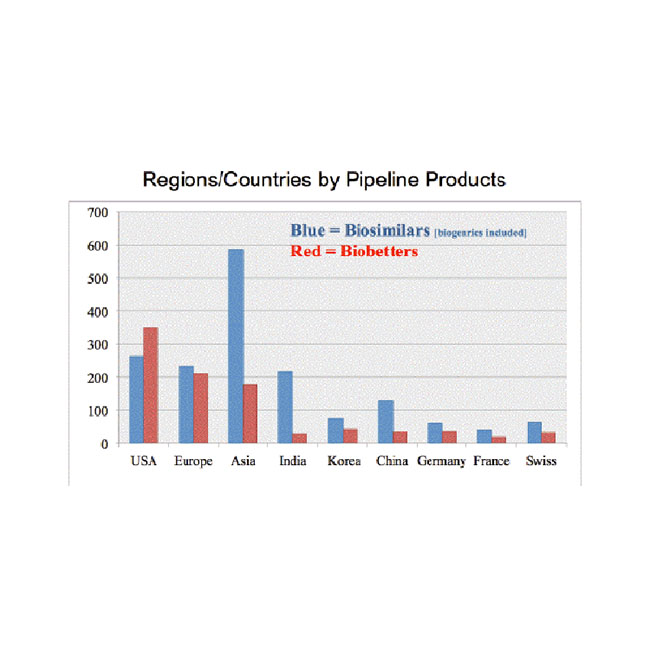

Establishing analytical similarity is the core of any biosimilar program. The FDA recent guidelines and some of my post explains some of the most recent guidances and FDA recommendations. This post is part 2 of 3 and provides some lessons to consider as a sponsor progresses through biosimilar development life cycle.. The information being shared comes from our review of many programs in US, EU, China and India.

The post is written very simply to convey some of the gaps that we have found and some thoughts of mitigation items for new and existing program. They come from the experience of our team and results from our methodology that is used for due diligence or preparation for global regulatory inspection. The lessons documented here represent some of the items we think are very important in readiness for product approval applications for both global or local markets.

Background

as noted in FDA biosimilar guidance, “unlike small molecule drugs, whose structure can usually be completely defined and entirely reproduced, proteins are typically more complex and are unlikely to be structurally identical to a reference product”. Therefore, a comprehensive analytical similarity is critical foundation for biosimilarity. Analytical similarity study is the first critical step for the sponsor’s biosimilar program and is also the key component for the regulatory agency in the totality of evidence in the approval of biosimilar products.

The following post will highlight the key points which we use in our approach for analytical similarity when a sponsor asks us for analytical similarity assessment of their biosimilar products for global registration.

Selection is important – Reference & Biosimilar lots

A key component of initiating the analytical similarity assessment plan is the selection of lots available for similarity testing. We suggest to sponsor a minimum of 10 lots of reference product and 10 lots of biosimilar to establish meaningful similarity acceptance criteria. To reduce the potential for bias and to conduct appropriate statistical analysis, the selected reference lots should be within the expiry period and their manufacturing dates should also vary. In other words, they should represent the shelf life of the reference product. The selected biosimilar lots should reflect the true variability of biosimilar product manufacturing. This sampling process will lead to precise and possibly accurate comparability of critical quality attributes for the analytical similarity.

The difference in the age of the proposed biosimilar and reference product lots at the time of testing may result in analytical differences. There should be a pre-specified plan to address how changes in the attributes over the shelf life will be incorporated into the determination of the similarity acceptance criteria.

Biosimilar Programs Last 5-7 years & Reference Product Expiration 2-3 yrs

A gap we often find in this area is that biosimilar program outlast the expiration date of the innovator product that has been procured. So in this case it is very difficult to conduct comparability through the life cycle of the development. This is key specially if there are changes in the process or product after the start of the clinical trials. The lots used to develop the analytical similarity exercises are typically expired by the time the clinical conduct is completed. The comparability required to show that a product remains the same pre and post clinical studies is dependent on the availability of material to conduct side by side studies. This complexity is why FDA recommends that you conduct your clinical study when you development is completed to avoid this very issue.

What some key considerations and options ?

(1) Wait till process is fully commercial ready prior to clinical start

(2) Minimize or push any changes to post approval

(3) Create internal drug substance and drug product reference standard and freeze -60 to -120

(4) If changes required use internal reference standard as your comparability baseline

(5) Create new reference standard for every major change and generate reference standard comparability study as you transition from old process to new process.

(6) Freeze all reference product material and thaw them when there is a need for major comparability study ( Will need to prove product stability)

(7) Generate Quality SOP(s) that will guide any of the requirements above.

Score it – Quality attributes & Potential impact

In the biosimilar development program, defining the quality attributes of reference product and categorizing them into Critical Quality Attributes (CQAs), Obligatory quality attributes and Non-critical quality attributes is a very important step. Quality attributes are defined as the physicochemical and functional properties of the target drug. Each quality attribute has clinical relevance and will have its criticality ranking based on its impact on clinical outcome. The overall assessment of quality attributes depends on three factors: – Clinical impact factor, Method risk factor and Process control risk factor. The categorization of quality attributes depends on their clinical impact and since the clinical impact factor is predefined and based on target drug properties, method risk factor and process risk factor are very crucial in criticality ranking score of each quality attribute.

Each analytical method should be qualified and/or validated prior to the analytical similarity study. The method risk factor is defined by its Sum of the Method’s Orthogonality, Capability, Sensitivity, and Output Factors. The process risk factor is defined by the capability and number of steps in controlling the quality attributes in the process.

Therefore, to score the quality attributes is very important in analytical similarity study. It helps the sponsor to evaluate the various risks that differences seen in analytical similarity assessment may pose.

Report card – Assessment of the study

The underlying presumption in the analytical similarity study is that a molecule shown to be structurally and functionally similar to a reference product will behave like the reference product in the clinical setting. The approach recommended by FDA to evaluate quality attributes for biosimilar products involves a statistical approach consistent with the principles set forth in ICH Quality Guidelines Q8, Q9, Q10 and Q11. The assessment of the analytical similarity study should be tier based. Tier assignments should be made to each test method based on the risk analysis and ranking of the CQAs. The tier(s) to which each test method is assigned determines the level of statistical rigor that will be applied to each test method result. Equivalence testing (Tier 1) is typically recommended for quality attributes with the highest risk ranking and should generally include assay(s) that evaluate clinically relevant mechanism(s) of action of the product for each indication for which approvals is sought. The use of quality ranges (Tier 2) is recommended for quality attributes with a lower risk ranking, and an approach that uses visual comparisons (Tier 3) is recommended for quality attributes with the lowest risk ranking.

What we often recommend is the following :

(1) Create a protocol to document the Quality Target Product Profile (QTPP) and put into change control and update as new data is developed.

(2) Create an SOP that guides both Non Key Process Parametes, Key Process parameters and critical process parameters and update with process understanding

(3) Develop a internal protocol or SOP that describes the most probable, likely or understood mechanism of action(s). This document is also updated as new information is collected from clinical understanding or published data from other programs.

(4) Develop risk assessment approach and use the risk ranking along with the understanding of methods expecificity, critical process parameters, process controls and mechanism of action to arrive at final risk ranking.

(5) Confirm with regulatory agencies the results of your analysis prior to fully implementing into the final similarity assessment that will be used to support your approval application.

Rigorous Methodology Required for Biosimilar Program Assessment

Lessons learned from our review of many biosimilar programs comes from our rigorous methodology we have developed internally. The items mentioned above are some of the important areas for consideration. If these gaps are not addressed early in the program it can lead to very difficult approval process.

If you have already started your clinical program and are still “tweaking” the process we will recommend that you review the items above. Develop a plan to ensure full comparability from lots manufactured before, during and after the clinical study commencement. The scientific bridge and comparability will be crucial in the approval process and if there exist a guiding documents ( suggested above) you will have basis for justification to the regulators.

I like to thank Roshan Upadhyay and Kamali Chance for co-authoring this article.

Roshan is our head of analytical and Kamali is our chief regulatory officer and both have extensive knowledge on biosimilar development for products like Enbrel, Herceptin, Neupogen, Neulasta, Avastin, Humira and others.

We hope these lessons learn can help your programs .As always we welcome your comments and if you like to connect with us please write to us Robert.Salcedo@biosciencescorp.com or upadhyay.roshan@qbdbiosciences.com or Kamali.chance@biosciencescorp.com