Donor Derived Supply Clift Risk(s)- Gene and Cell Therapy Companies

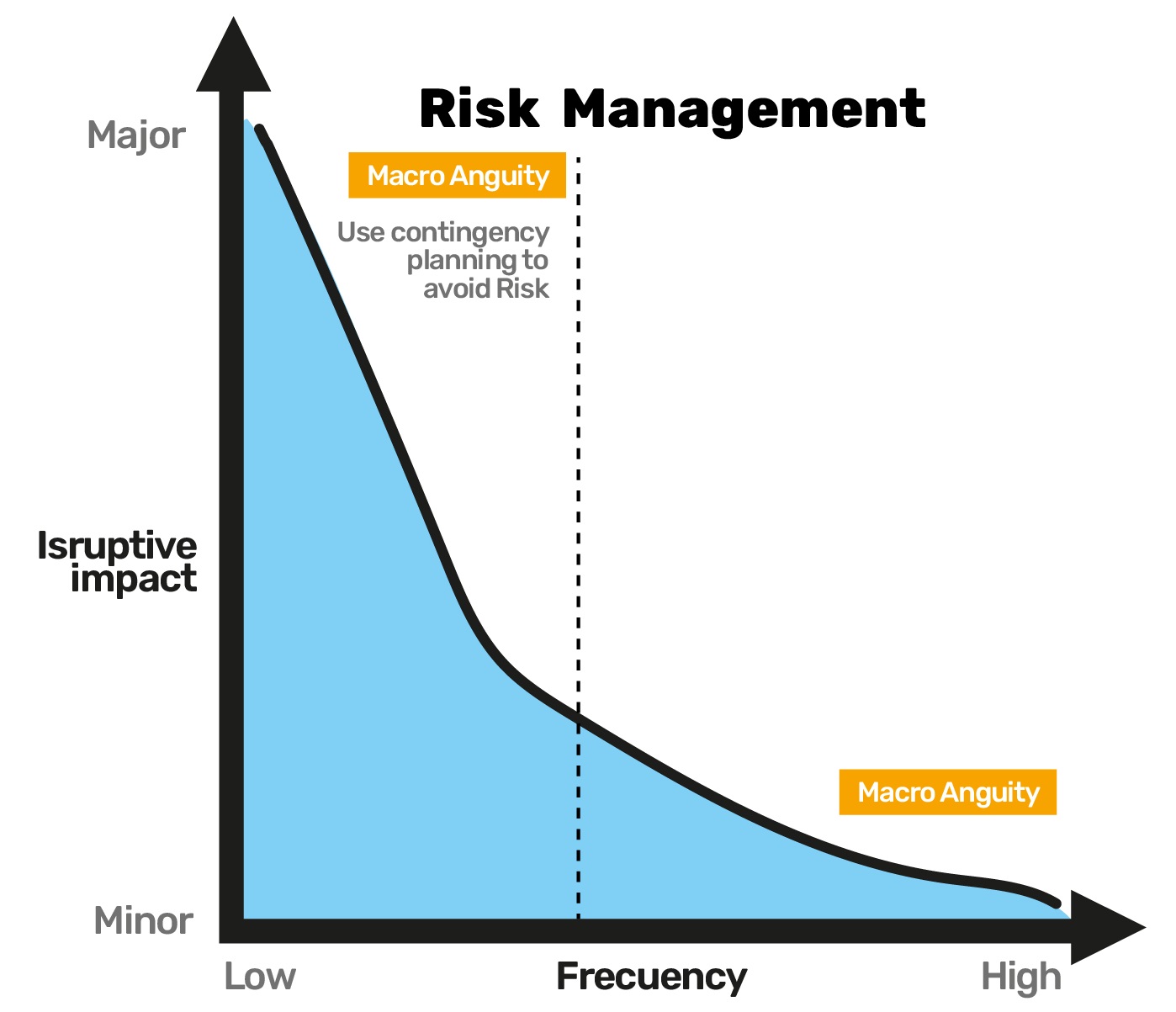

As of this writing there are more than 40 companies using donor-derived cells to manufacture their intended version of cell-based therapies. Further a review of the pipeline and the stage of development of each entry in the pipeline indicates a potential for many of these products to come into the market, simultaneously. The potential convergence of events and the patient requirements is likely to overwhelm the supply chain and availability of the Donor derived raw material. As indicated in the figure above this disruption may significantly impact a company’s financial and, most important, impact patient supply. The combination of the potential successes of these companies coupled with low birth rates in the USA maybe a recipe for a disconnect between the patient needs and the supply of donor derived blood products.

One of the worries with Gene and Cell Therapy is the supply chain and security of donor derived critical starting materials. For cord blood this is especially worrisome as the birth rate is USA is about 12 births per every thousand according to microtrend (https://www.macrotrends.net/countries/USA/united-states/birth-rate). Top companies such as Nkarta, Takeda, Cellularity, Cytoimmune, Artiva, Kiadis, and Catamaranare companies rely on donor derived material to support their current and future commercial products. We anticipate that if 50% of these companies get to commercial scale which require thousand of donors, they will easily consume most of the donor materials currently available in the market. If our calculations are right and the birth rate trend continue to flatline, there will be less than five million cord blood available in 2025 which will not be enough to cover the patients requiring this medically necessary therapeutics. The issue exacerbates if the dose regimen requires more than 1 dose per month.

Using the statistics from macrotrend coupled with launch forecast from these top Gene and Cell companies, there is high likelihood of a supply mismatch between the required donor material with the commercial supply by 2025. As of part of risk mitigation actions, companies supply chain organizations should consider building cell banks as part of their commercial readiness plans. The disruptive potential and lack of donor derived raw material during product launch poses both financial and patient risks. The companies who are relying on just in time donor derived material should evaluate an inventory build up plan. This may take 2-3 years to build as the constraint continues to grow as companies transition from small clinical trials to larger trials with larger patient population.

To address this macro and micro risk issue Ocyonbio Puerto Rico (PDMO) has created the Puerto Rico Cell Processing business unit with the mission to create long term frozen cell banks with phase appropriate testing to support R&D, clinical and commercial launch. Puerto Rico Cell Processing is part of OCYONBIO Partnership development organization. The goal of PRCP is to reduce the complexity of donor derived blood products with Leukapheresis or cord blood origin.

Our process envisions the creation of pre-certified cell banks by generating a highly concentrated, frozen repositories with target cells in a vial. The banks will consist of harvested target cells that can be frozen and shipped to a manufacturing facility for further processing. The banks will be tested for advantageous agents, sterility, Mycoplasma and Endotoxin. The banks will consist of key target cells that can be used for both R&D and cGMP further processing. We anticipate having a bank for NK cells, TREGS, B, T and other target cells that can be isolated using a closed system and frozen in standard preservative free buffer that will ensure viability and activity.

The goal of creating cell banks is to reduce blood processing requirements within an existing facility, while simultaneously reducing supply risks. The final frozen banks can be stored from 2-5 years to support long term patient needs. Our plan is to ship vials with a min 10^7 cells/ vial which will allow for R&D and clinical manufacturing to be started with 2-10 vials. We envision partnering with companies to develop a replenishment cycle 2-5 years prior to their launch, the cycle will balance the consumption and supply to achieve a targeted inventory level.

Our cGMP process will use state-of-the-art equipment to conduct a closed process for isolation with full cGMP testing rendering sterile and adventitious agent-free products. We have engaged a group of blood services to procure large quantities of samples from across the country allowing us to create a multi-year bank that can support clinical and commercial operations.

In addition, the creation of the critical raw material also reduces the complexity of managing a blood processing step within the existing manufacturing process. We envision our banks being thawed at the cGMP site and allowing the manufacturing process to be started reducing complexity and risks. The banks also have additional benefits by removing un-needed manufacturing steps and reducing manufacturing cycle time which can reduce manufacturing and testing cycle times by more than 1 week.

Puerto Rico Cell Processing intends to provide these services as either stand alone or part of a replenishment contract that will provide continuous flow of donor derived critical material for long term storage.

Our goal is to create a supply model to reduce the long-term risk of a dwindling supply of donor-derived material, as the top companies move through their clinical trials and eventual commercialization. The combination of this potential demand combined with decreasing USA birth rate represents a grave risk to supply and most important patient access during the commercialization and distribution of these products which are addressing critical medical needs.

Puerto Rico Cell Processing (PRCP) is located in Puerto Rico and uses FDA regulations to govern their cGMP manufacturing process. The banks will be shipped with certificate of analysis complying the phase appropriate nature of the development stage(s). The minimum testing will ensure the banks comply with USP and FDA levels for mycoplasma, endotoxin and sterility and (others as required by client).